LEUCHTEN + METALL TECHNIK GMBH

CORE COMPETENCES

For your successful project.

LMT Leuchten + Metall Technik GmbH specialises in the development and the production of tailor-made solutions for lighting projects and metal work. Our portfolio comprises lighting tubes and luminaires for train stations, products for technical lighting, various solutions for the illumination of architecture, as well as housings and metal parts for medical technology, machinery, interior construction as well as objects of art and design.

With various luminaire families and a special modular light construction system, LMT provides products, which perfectly suit the needs of an energy efficient indoor and outdoor illumination of offices, schools, retail shops and also residential buildings. With the standardized components of the LMT light construction system “Lichtbaukasten”, new individual luminaires can also be designed very cost-effectively.

All of our individual lighting solutions are based on the design idea of the planner. In close co-operation with the customer and the planners, we examine the lighting technology and the shaping of each of our fixtures, regarding to architecture and function they are designed for. Upon request, we evaluate the lighting design and effect in a real or a virtual environment and adapt them as needed for each project. This allows us to offer concept-compliant solutions for every lighting scenario using our extensive knowledge on luminaire manufacturing.

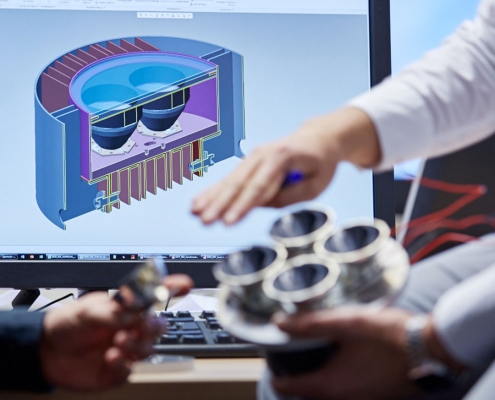

DEVELOPMENT + DESIGN

Our in-house development and design division provides sophisticated solutions of lighting, metal and technological tasks from a single source. In close co-operation with our customers – lighting designers, architects and owners – we develop solution concepts in accordance with their individual specifications.

Thanks to the use of parametric 3D design software in all project phases, our designers are able to import existing CAD data of customers and planners into our system and continue working directly on this basis. In this way we develop in close dialog with our customers the lighting technology and shaping of each product with perfect adaption to architecture and function.

LIGHTING PLANNING

Up to a certain extent, we are able to solve small light planning tasks using LMT luminaires, by means of special lighting design programs. This allows to visualise various interior and exterior illumination scenarios with LMT luminaires already during the planning process.

For complex lighting situations and extensive projects we recommend to our customers to integrate the expertise of renowned lighting designers.

Interdisciplinary co-operation with specialists for control, media and stage technology enables us to implement lighting scenarios exactly according to the specifications of our clients.

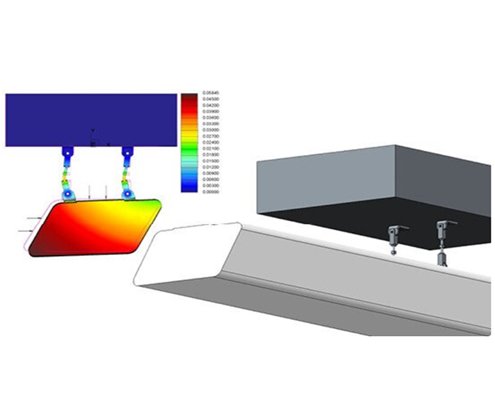

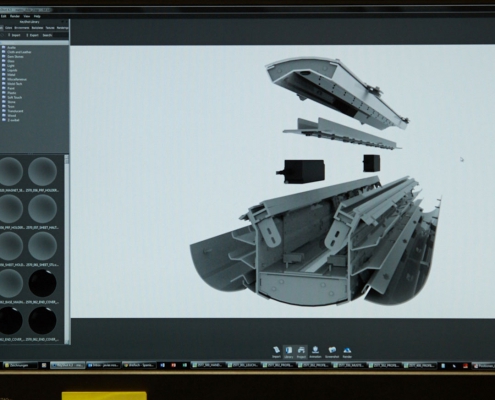

SIMULATION + VISUALISATION

Right from the start of the product development process, our designers apply rendering and simulation software to generate photorealistic images of the preliminary products and place them in the intended environment.

Furthermore they are able to visualise the structural-mechanical and thermal product behaviour by means of FEM analyses. Today, the precision of this method usually replaces the time-consuming and costly construction of physical prototypes.

PROTOTYPE + SAMPLE CONSTRUCTION

In spite of existing digital and virtual possibilities for analyses and visualisations it is in some cases nevertheless necessary to construct prototypes or luminaire samples: for presentations, for the evaluation of shaping and haptic of a product in the original scale or for lighting tests to demonstrate the light effect on-site.

Thanks to our flexible production, this can be realized without problems.

PRODUCTION +

CONTRACT MANUFACTURING

For the fabrication of small and medium series of high-quality metal products, our experienced manufacturing team uses an innovative machine pool in our in-house production facility. We provide job order production services for our customers, comprising complete products as well as single metal parts or assembly units.

LMT products are sustainable by principle: due to their thoroughly design and utmost manufacturing precision, they guarantee durability and the conservation of ressources. Furthermore we keep our CO2 footprint at a minimum by using our own photovoltaic plant on our companies roofs.

BESPOKE SOLUTIONS

For the individual lighting or metal projects of our customers we develop tailor made solutions either by customising our serial luminaires or by designing completely new products.

From the first draft to the installation on site: In partner-oriented co-operation, we bring their ideas to life, no matter whether a full solution, a single luminaire, serially produced parts or special products are needed.

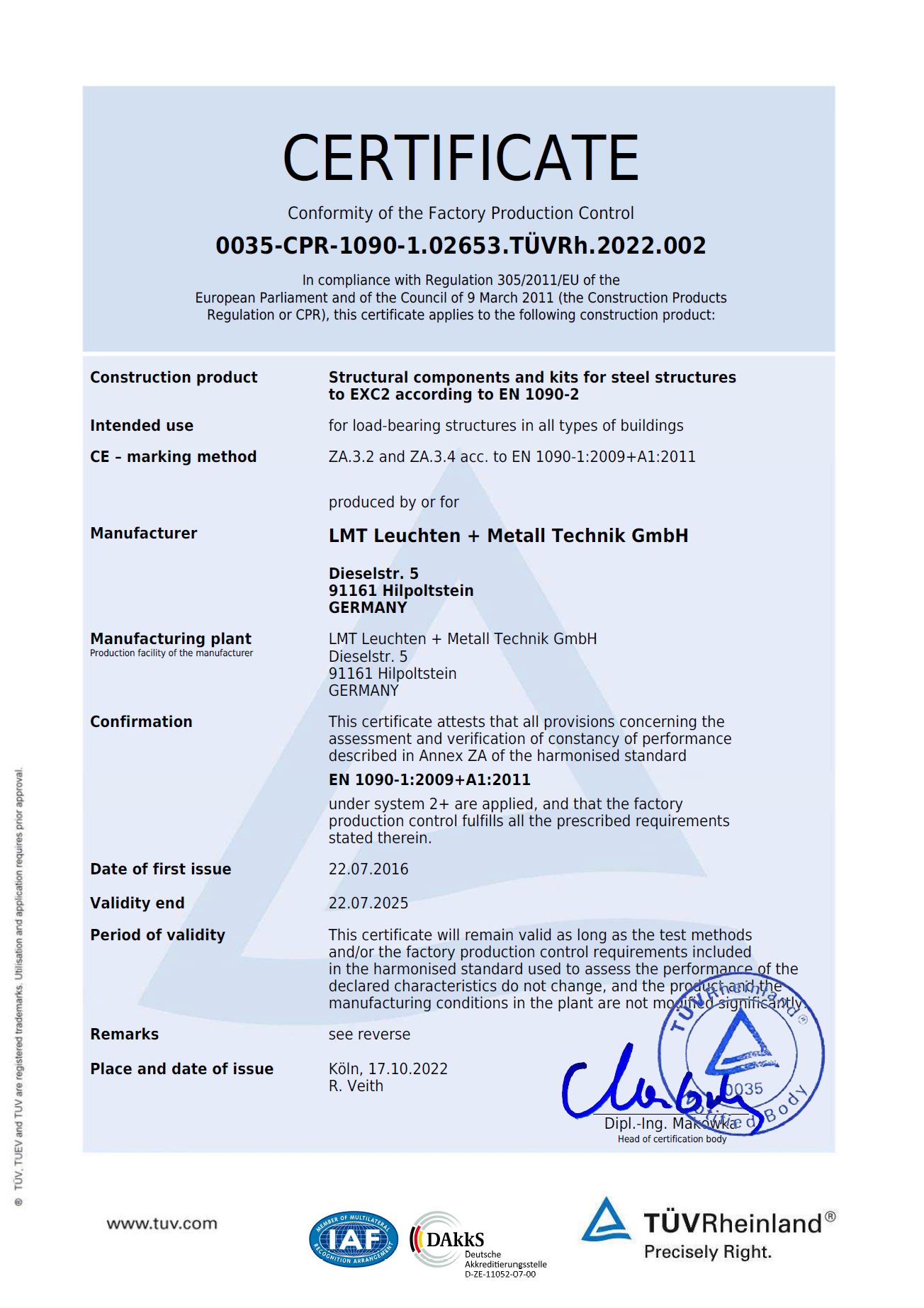

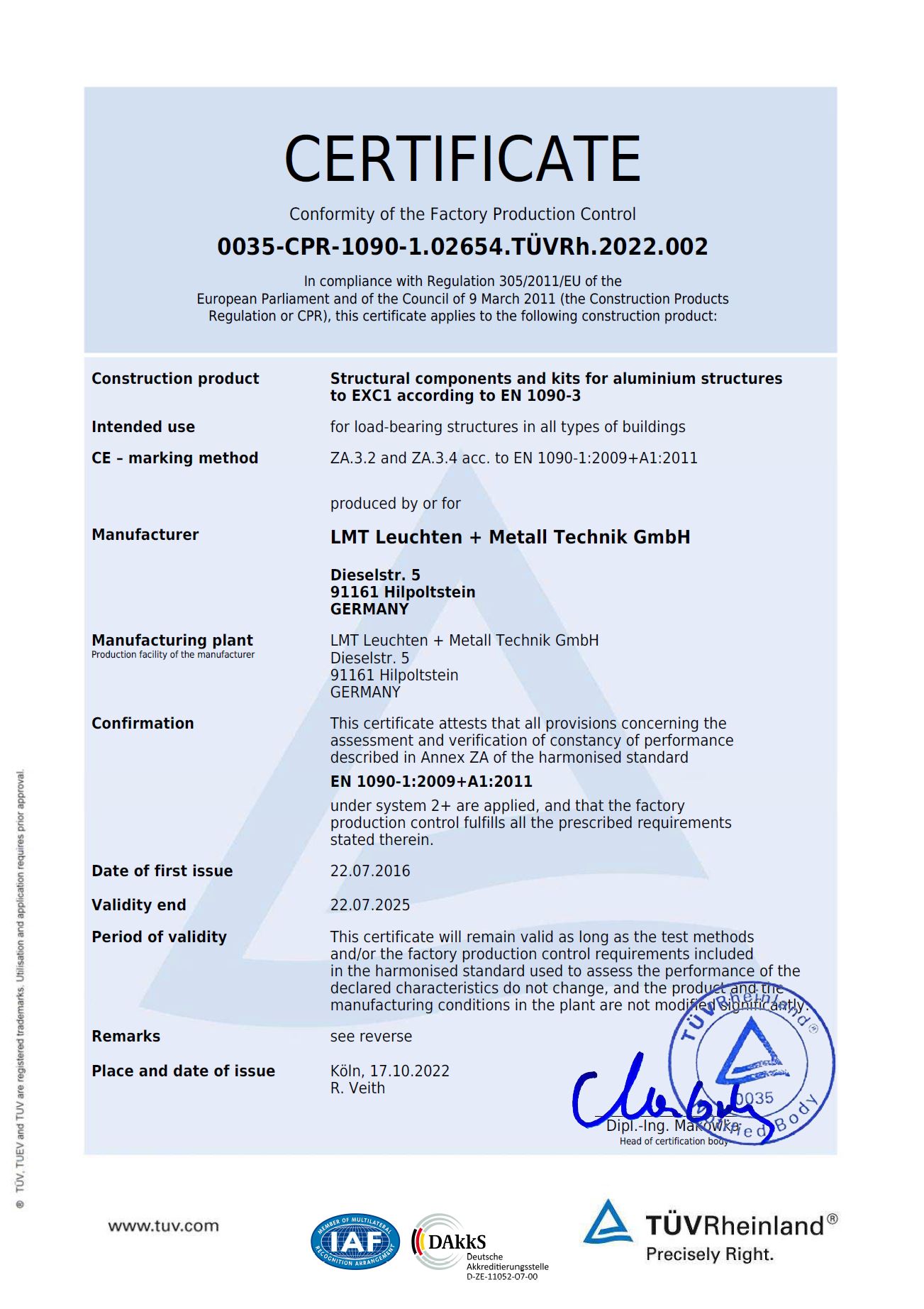

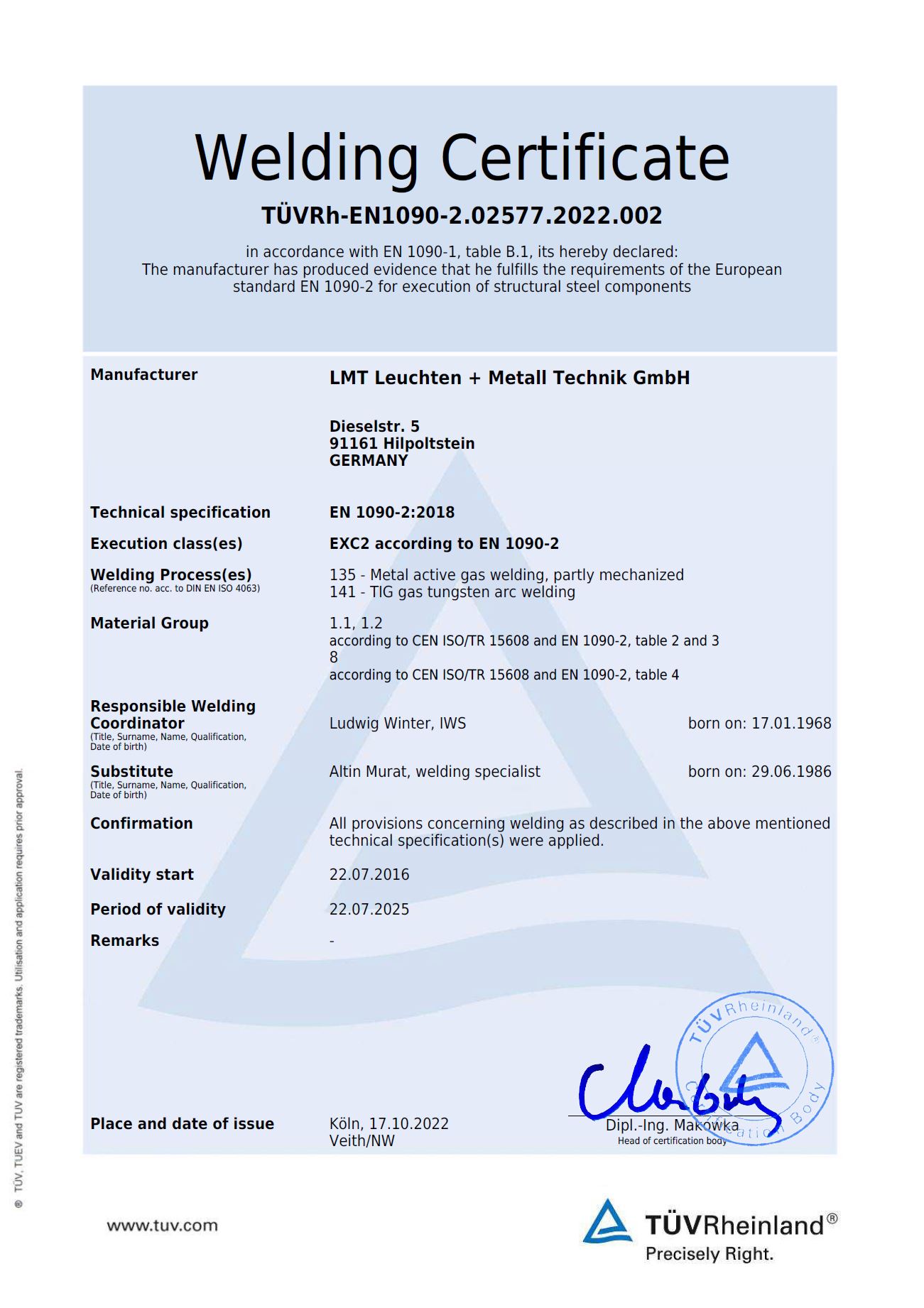

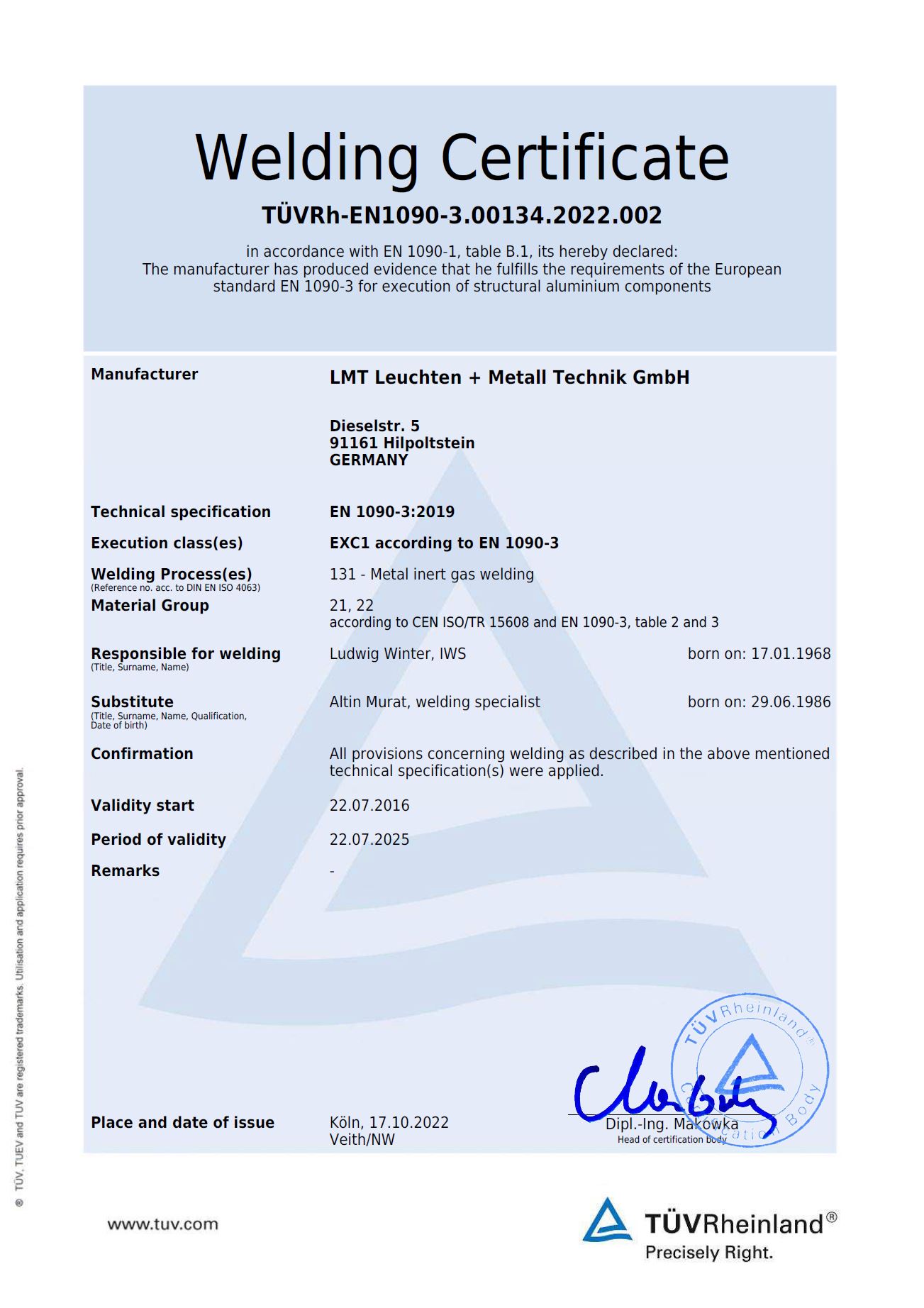

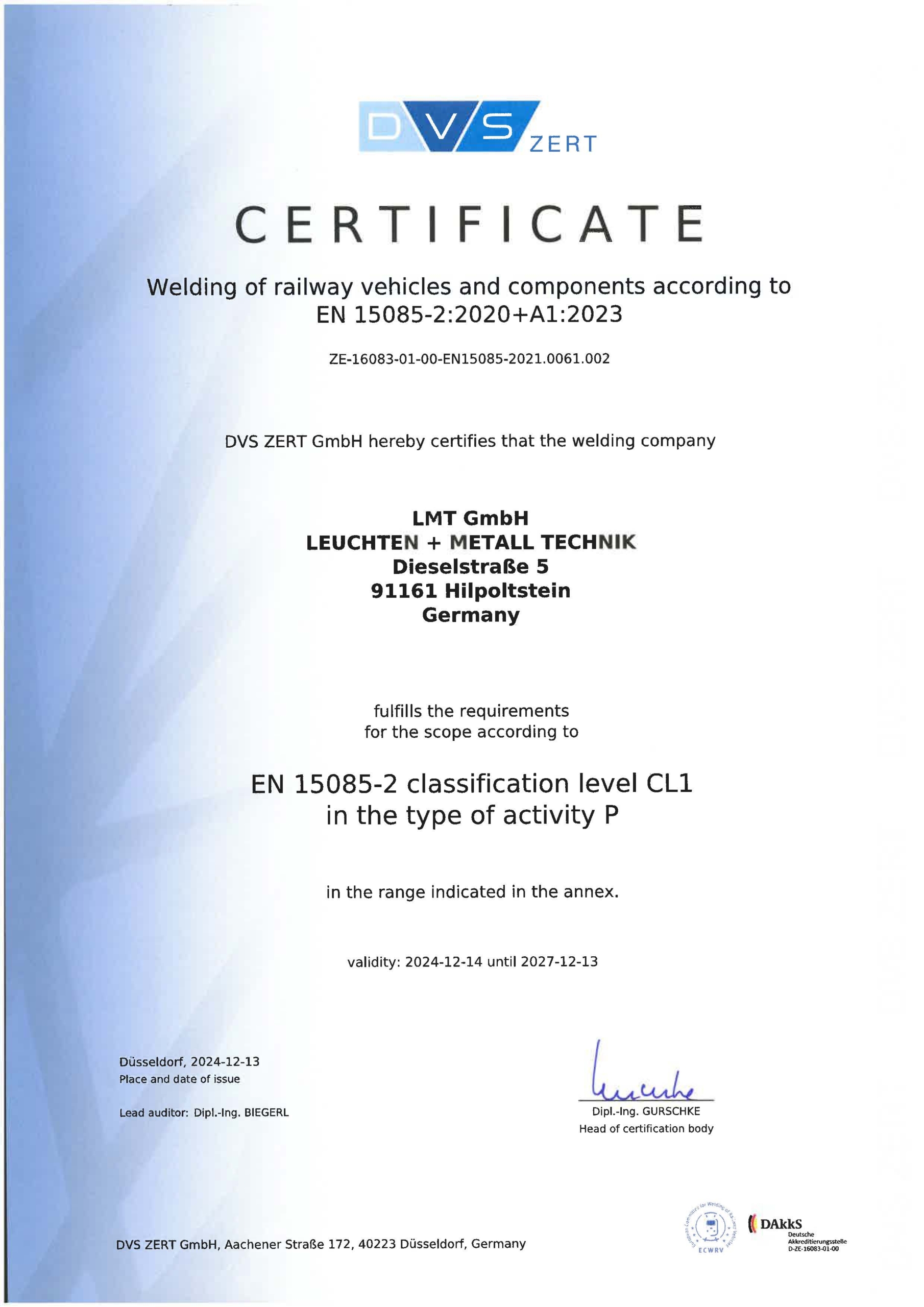

CERTIFICATIONS

Our certifications underline our commitment to the quality and safety of our products for the benefit of our customers:

- Certified quality according to ISO 9001:2015

- Environmental certification according to ISO 14001:2015

- Certified welding according to EN ISO 3834-2

- Certified in-house production control according to DIN 1090-1, 1090-2, 1090-3

- Certified welding of railway vehicle components according to DIN EN 15085-2 CL1 / P