LEUCHTEN + METALL TECHNIK GMBH

ASSEMBLY PRODUCTION WITH A SYSTEM – EVERYTHING FROM ONE SINGLE SOURCE

From individual parts to complete assemblies: precise production, assembly & logistics – your contract manufacturing partner in metal construction.

RELIABLE PARTNERSHIP

Leuchten + Metall Technik GmbH is at your disposal as your competent partner in the field of CNC contract manufacturing for metal products made of sheet metal. With the most modern machines – mainly from Trumpf – our qualified employees process orders for renowned customers from various areas of industry and trade.

WHAT TO EXPECT FROM LMT

EXTENSIVE EXPERIENCE

We stand out with many years of experience in CNC production – from simple bending parts to complex assemblies, from prototypes to small and medium series – also for your projects. International orders are no problem for us either. If needed, we provide the necessary approvals and certificates for the various processing methods.

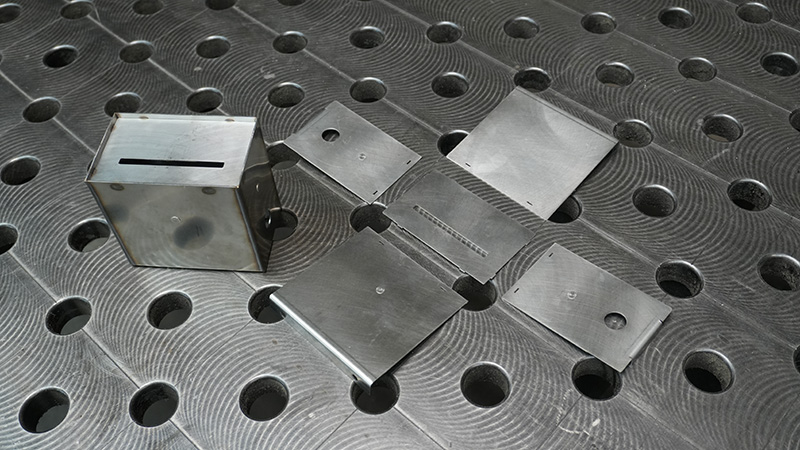

Complete solutions instead of individual parts – your assembly, our project

We provide more than just metal parts: As an experienced contract manufacturer, we take on the complete production and assembly of your assemblies – efficiently, precisely and on time.

- Production & assembly of complete metal assemblies

- Mechanical processing, laser cutting, welding, bending, grinding

- Production according to your drawing

Have your assembly manufactured now!

Laser beam cutting

Our CNC-controlled laser cutting systems enable precise, clean and fast processing of various metals.

- Precise cutting edges without reworking

- Stainless steel, aluminum, steel

- From custom-made products to series production

Laser beam welding

Innovative technology for precise weld seams in perfect technical and visual quality.

- Perfect welding results even with components of different thicknesses

- Consistently high weld seam quality without time-consuming reworking

- Ideal for high quantities

Welded joints for rail vehicles in accordance with DIN EN 15085-2 CL1/P

We supply every welded interior and exterior component for your rail vehicle, from quantities of 1 to large series, in consistently high quality and on the desired call-off date.

- Certified in accordance with DIN EN 15085-2 CL1/P

- Material according to customer specifications

- Consistently high quality thanks to controlled laser welding

Folding & Bending

CNC-controlled bending for precise curves and edges with high repeat accuracy.

- Implementation of complex geometries

- For stainless steel and steel sheets as well as aluminum

- Highest precision for series production and individual pieces

Branches & application areas

Precise assemblies and metalworking for your business

- Mechanical engineering – High-quality metal assemblies & individual parts for industrial applications

- Rolling stock manufacturing – Perfectly welded assemblies certified to meet the requirements of Deutsche Bahn

- Medical technology – Highest precision for safety-relevant applications

Why choose LMT?

FAQ – Frequently asked questions about assembly production & contract manufacturing

Gallery

Complete solution instead of partial solution

We manufacture your assemblies completely, efficiently and in top quality.

Request your offer now – project-related delivery times, personal service, high-quality results.

We will be happy to help you realize your project. Benefit from our experience from countless individual projects and contact us now!